Don't Get Infected by Old & Traditional Equipments.

International Equipments

Budget Treatment

Experts

Scheduled Work

Ultraviolet Light Chamber

Today, UV light technology is the preferred choice for sterilization in numerous industrial applications because of its effectiveness, affordability, and most importantly, its safety. UV light is a disinfection method that inactivates microorganisms by a physical process rather than using harmful chemicals, and thereby, does not produce corrosive materials or disinfection by-products (DBPs). The short-wavelength ultraviolet (UV-C) lights are used to destroy nucleic acids and disrupt the DNA, thus rendering them unable to perform vital cellular functions including the ability to reproduce or infect.

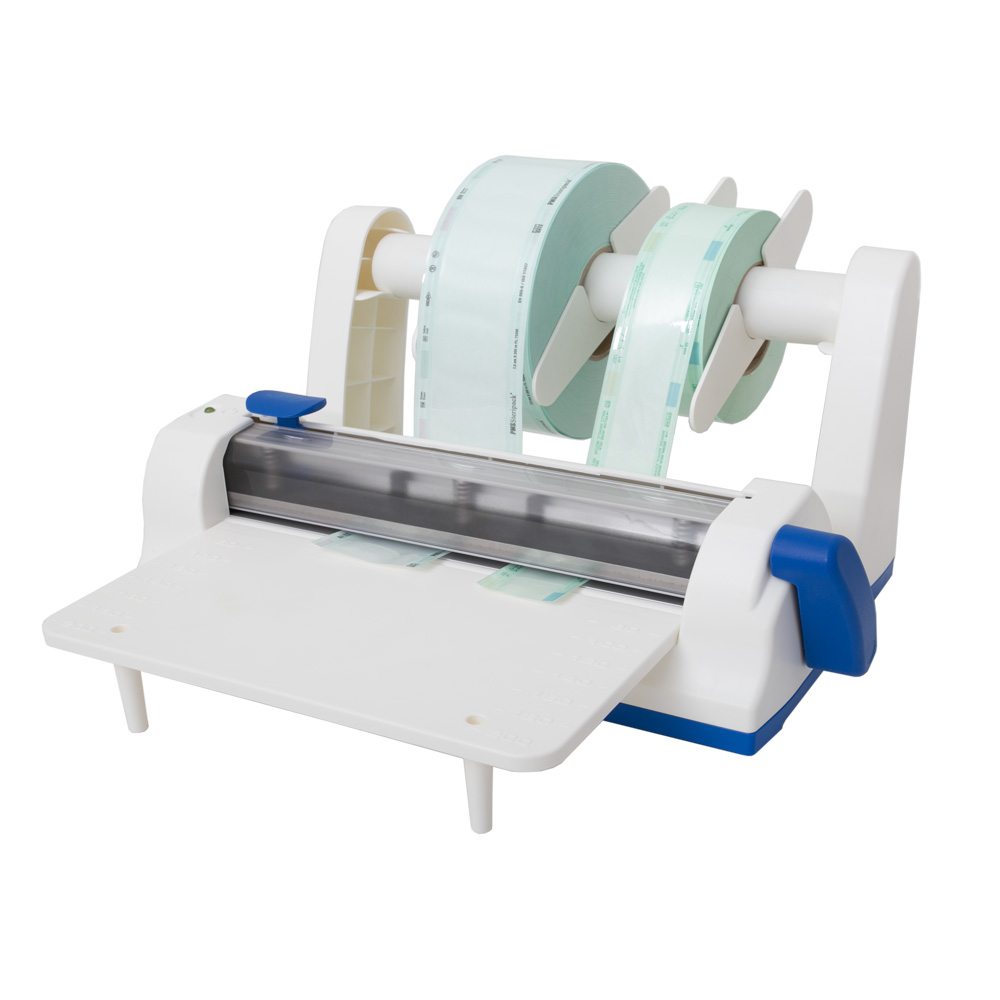

Dental Pouch Sealer

Dental heat sealers are used with sterilization tubing and similar materials to create custom-sized sterilization packaging. These simple devices heat up quickly and allow the packaging material to be placed beneath an arm that presses it into the heating element to create a proper seal. A heat sealer should be simple to use, and having the ability to set the heat level can allow it to work with multiple materials. A heat sealer should fit on a counter in the sterilization center for easy access.

Steam Autoclave

An autoclave is a pressure chamber that is used to sterilize equipment and supplies. When these items are placed inside the autoclave they are exposed to high temperature steam (usually around 132 degrees Celsius or 270 degrees Fahrenheit) for about twenty minutes.

Ultrasonic Vibrator Sterilizer

We use it to ensure germ less treatment. Ultrasonic cleaning uses cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics.

Glass Bead Dry Sterilizer

The stainless steel, central well is filled with dry glass beads that are heated to 233°C. Simply insert an instrument into the beads and, within 15 seconds, the submerged portion of the instrument is sterilized. It’s that easy!